Cochran boiler: parts, working, uses, advantages, limitations with PDF

A Boiler is an important part of a steam power plant and today we’ll see one such type of boiler called the “Cochran boiler“.

So, What is a Cochran boiler? what about its construction, working, advantages, uses? all of these questions answered at The Mechanical post.

Download the PDF on the Cochran boiler given at the end of the article.

What is a Cochran boiler?

A Cochran boiler is a vertical axis, multi-tubular fire tube boiler that operates at low pressure having natural circulation. The Cochran boiler is portable and has a thermal efficiency of about 70% when coal-fired and 75% when oil-fired.

The Cochran boiler is a modified form of the simple vertical boiler and has higher efficiency than that of the simple vertical boiler.

Cochran boilers are used where steam is required at low pressure and the steam generation rate is low, unlike Lamont boiler, which is capable of producing steam at high pressure, temperature, and the generation rate is high.

Must read: What are fire tube and water tube boiler?

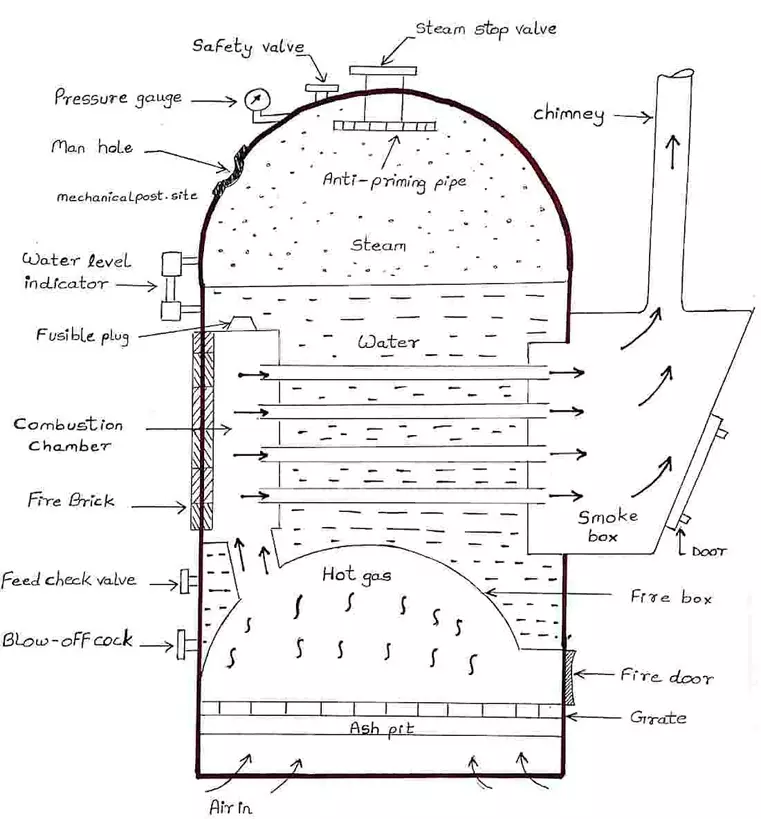

Construction of Cochran boiler

- Boiler shell

- Grate

- Ash pit

- Fire box / Furnace

- Flue pipe

- Combustion chamber

- Fire tubes

- Anti- priming pipe

- Smoke box

- Chimney

- Man hole

- Boiler mountings and accessories

Copyright – The Mechanical post

Boiler shell

The shell of the Cochran boiler is the main cylindrical outer body that is hemispherical at the top.

The shell is an important structure of the boiler. The top hemispherical part helps increase the volume of the boiler.

Grate

The grate is a plate having cut out in it for air to pass through it. The coal is placed on the grate and burnt.

Ash pit

The ash formed by the combustion falls below the grate and is collected in the ash pit provided below.

Fire box / Furnace

It is a dome-shaped structure at the bottom of the boiler wherein the coal is burnt and hot gases are produced.

The dome shape of the firebox helps in reflecting back the hot gases before exiting through the Flue pipe.

Flue pipe

The flue pipe is a pipe used to connect the firebox with the combustion chamber.

Combustion chamber

The hot gases from the firebox enter the combustion chamber. It is lined with fire bricks which act as a refractory material and help prevent heat from escaping.

Fire tubes

Several horizontal tubes called fire tubes are attached to the exhaust of the combustion chamber. These tubes are surrounded by water. The hot gases travel through these fire tubes, thereby heating the water.

Anti-priming pipe

The anti-priming pipe prevents water droplets in the steam to be carried away.

Smoke box

The end of the fire tubes is connected to the smokebox. The function of the smokebox is to trap the dust, ash fuel, or other particles before letting them off into the atmosphere.

The smokebox is provided with a smoke door for cleaning the fire tubes and the smokebox.

Chimney

The gases from the smokebox are let off high up into the atmosphere via the chimney.

Man hole

The manhole is an entrance to the boiler for inspection and maintenance of the boiler. As shown in the picture, the manhole is situated at the top of the Cochran boiler.

Boiler mountings and accessories

The boiler mountings and accessories are the devices that help in the proper functioning of the boiler and help increase its efficiency, some of them used in the Cochran boiler include:

Water level indicator: To indicate the level of water inside the boiler

Pressure gauge: To monitor the steam pressure inside the boiler.

Safety valve: To let off the steam to the atmosphere when steam pressure reaches dangerous levels

Steam stop valve: To regulate the amount of steam coming out of the boiler.

Blow off valve: To drain off the boiler for maintenance and inspection and also remove the sediments settled at the bottom of the boiler.

Fusible plug: To protect the firebox and fire tubes from burning when the water level falls to an unsafe level by letting the steam escape the boiler.

We just happen to have an article on working on each of the boiler accessories and mountings, which might be very helpful for you.

Do you know?

Any type of fuel, be it diesel or oil, or coal can be used in the Cochran boiler.

Working of Cochran boiler

The coal is placed and ignited onto the grate, inside the firebox. The coal is fed through the fire hole. Fresh air enters the boiler from the bottom and the combustion of coal produces hot gases.

These hot gases then enter the combustion chamber via the flue pipe. The fire brick lining prevents escaping of the heat in the hot gases.

The gases travel through the combustion chamber and enter into the fire tubes.

Source – Andy Dingley, CC BY-SA 3.0, via Wikimedia Commons

The hot gases give up their heat to the fire tubes. The tubes then heat the surrounding water via convection. This results in the conversion of water into steam.

The flue gases from the fire tubes then go through the smokebox wherein any particles of ash, coal, or dust are collected there.

The flue gases are then let off into the atmosphere via the chimney.

This process goes on and steam is generated in the Cochran boiler.

You might also like to read:

- What is a Nuclear power plant?

- Gas turbine power plant – construction and working

- Mechanical properties of materials

Applications of Cochran boiler

- Paper industries.

- Refining industries.

- Chemical processing units.

- Different process applications.

Advantages of Cochran boiler

- The Cochran boiler is easy to operate.

- It can be transported easily.

- It has a low initial cost.

- Any type of fuel can be used.

- The boiler is vertical, hence less floor area is required.

Disadvantages of Cochran boiler

- It has a limited pressure range.

- The steam generation rate is low.

- It is hard to inspect and maintain.

- Not suitable for high-pressure steam generation.

This brings us to the end of the article on Cochran boiler. What are your thoughts on it? do let us know in the comments.

Also, don’t forget to share this article with fellow engineers. Will be back with another informative article. Till then Keep Learning!