The Impact of Industrial Automation: Revolutionizing Seafood Packaging

Hello there fellow Engineers! Today at The Mechanical post we have a wonderful topic to discuss about i.e. Industrial automation. Moreover, we’ll be taking a look at the fishing & packaging industry in particular and how industrial automation is helping it grow.

In the world of industrial packaging, machines have undergone a significant evolution, especially in the fish processing industry. Traditionally, this sector relied heavily on manual labor for packaging, but with the advent of technology, automation has become a game-changer.

According to a report by the Food and Agriculture Organization, the global fish production reached a record high of about 179 million tonnes in 2018, with aquaculture representing 46% of the total. This surge in production necessitates more efficient packaging methods to ensure freshness and quality.

source: Food and Agriculture Organization of the United Nations

Automation in packaging not only addresses these needs but also significantly enhances production efficiency.

The integration of automation in packaging machines has revolutionized how the fish processing industry operates.

In the early days, packaging was time-consuming, labor-intensive, and prone to errors. Now, automated systems offer precision and speed, which are crucial in handling perishable items like fish.

A study highlighted that automated packaging could increase productivity by up to 70%, a testament to its transformative impact.

The significance of this transition cannot be overstated. As the industry continues to grow, the demand for efficient packaging solutions escalates.

Automation in industrial packaging machines is not just a trend but a necessity to keep up with the increasing global demand for fish and seafood products.

This article explores the role of automation in modern and used packaging machines, focusing on its evolution, components, benefits, challenges, and future trends.

Evolution of Packaging Machines

The journey from manual to automated packaging in the fish processing industry mirrors the overall technological progression in industrial manufacturing. Initially, packaging processes were rudimentary, involving manual labor for sorting, filling, sealing, and labeling. However, with the onset of the industrial revolution and subsequent technological advancements, a shift towards automation began.

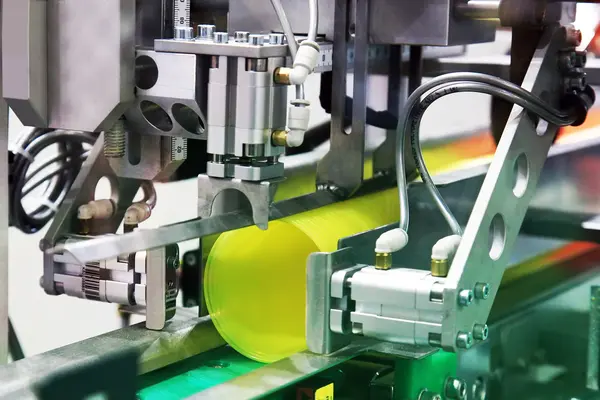

The introduction of conveyor belts, pneumatic systems, and later, robotic arms, marked the beginning of this transformation. These innovations allowed for the faster movement of products, precise placement, and eventually, the automated sealing and labeling of packages.

The automation era truly began with the integration of computer-aided design and manufacturing systems, which brought about a new level of precision and efficiency in packaging.

Key Components of Automated Packaging Systems

In an automated packaging system, several key components work in tandem to ensure efficiency and accuracy. The heart of these systems lies in their machinery, which often includes:

- Conveyors,

- Fillers,

- Sealers,

- Labeling machines.

- Electro-mechanical hardware

- Automation control hub & software

In the fish processing industry, these machines are designed to handle delicate products delicately, ensuring that the quality of the fish is maintained throughout the packaging process.

Software plays a pivotal role in automation. It enables the precise control of machinery, timing, and coordination of the packaging process. The software also allows for quick adjustments to accommodate different sizes and types of packaging, which is particularly useful in an industry with such a diverse range of products.

Robotics has been a groundbreaking addition to packaging systems. Robotic arms, equipped with sensors and end-effectors, can perform tasks such as picking and placing items, which were previously done manually. This not only speeds up the process but also reduces the risk of contamination – a crucial factor in the fish processing industry.

Benefits of Automation in Packaging

The advantages of automation in the fish processing industry are numerous. Firstly, it significantly increases efficiency and productivity. Automated machines can operate continuously without fatigue, leading to higher output. This is essential in meeting the growing global demand for fish and seafood.

Accuracy and consistency are other significant benefits. Automated systems ensure that each package is filled, sealed, and labeled uniformly, reducing the margin of error and waste. This consistency is vital for maintaining brand reputation and customer trust.

From a safety perspective, automation reduces the need for direct human contact with the product, thereby minimizing the risk of contamination. Moreover, it also reduces labor costs, as fewer workers are needed to manage the packaging process.

Case Studies: Successful Implementations

Several case studies illustrate the successful implementation of automation in the fish processing industry. For example, a Norwegian salmon processing facility implemented a fully automated packaging line, which resulted in a 60% increase in packaging speed and a 30% reduction in labor costs. Similarly, a cod processing plant in Iceland adopted robotic systems for packaging, leading to a 50% increase in overall efficiency.

These case studies demonstrate not only the feasibility of automation in this industry but also its potential to significantly improve operations.

Challenges and Limitations

Despite its many benefits, automation in packaging also comes with challenges. The initial investment in automated machinery can be substantial, making it a significant decision, especially for smaller companies. The complexity of some products can also pose a challenge, as machines must be sophisticated enough to handle different shapes, sizes, and types of fish.

Another challenge lies in the maintenance and upkeep of these automated systems. The sophisticated technology and machinery require specialized knowledge for maintenance and repair, which can be a hurdle for companies without access to skilled technicians.

Additionally, adapting to rapidly changing market demands and maintaining flexibility in packaging different types of fish products remains a challenge for fully automated systems.

Future Trends in Packaging Automation

Looking towards the future, the packaging automation industry, particularly in the fish processing sector, is poised for further innovations. Emerging technologies like artificial intelligence (AI) and machine learning are expected to play a significant role. These technologies can enhance the adaptability of packaging machines, allowing for real-time adjustments and optimization based on changing parameters such as product size or packaging material.

The integration of the Internet of Things (IoT) in packaging machines is another trend that’s gaining traction. IoT-enabled devices can monitor various aspects of the packaging process, from machine performance to environmental conditions, ensuring optimal operation and timely maintenance.

Furthermore, there is a growing focus on sustainability in packaging. Automated systems are increasingly being designed to use eco-friendly materials and minimize waste, aligning with global efforts to reduce the environmental impact of packaging.

Conclusion

The role of automation in modern industrial packaging machines, especially in the fish processing industry, has been transformative. It has not only increased efficiency and consistency in packaging but also played a critical role in meeting the rising global demand for fish and seafood products.

While challenges exist, particularly in terms of investment and adapting to diverse products, the benefits far outweigh the drawbacks. With ongoing advancements in technology, the future of packaging automation looks bright, promising even more efficiency, flexibility, and sustainability.