What is a Slip gauge? its types, wringing process, and uses.

Today at The Mechanical post we’ll discuss What is a slip gauge? the different grades of slip gauges, the wringing process of slip gauges, as well as take a look at its applications.

What is a Slip gauge?

Slip gauges also known as Gauge blocks or Johannson gauges are cuboidal-shaped blocks of high-grade steel with a high finish. They are used mainly used as measuring standards in the engineering field.

These are first hardened to resist wear and carefully stabilized so that they are independent of any subsequent variation in size or shape.

The longer gauges in the set and length bars are hardened only locally at their measuring ends.

After being hardened, blocks are carefully finished on the measuring faces to such

a fine degree of finish, flatness, and accuracy that any two such faces when perfectly clean may be wrung together.

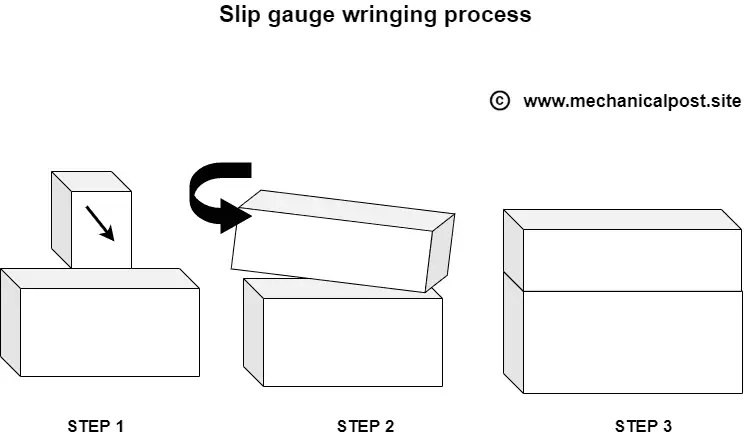

Procedure of wringing slip gauges

The two slip gauges in precision measurement are joined by the process called “wringing”

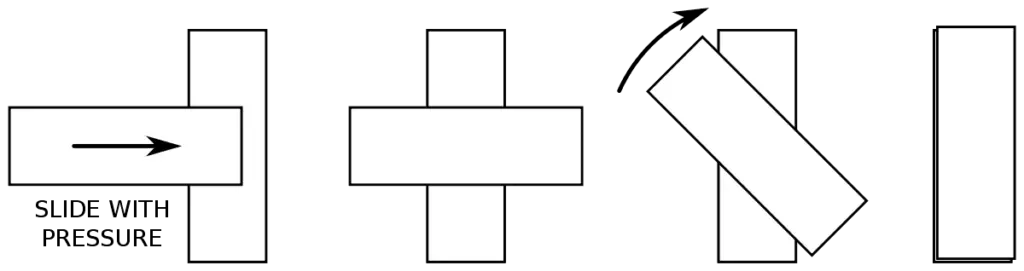

Front view of the wringing process

Top view of wringing process | Image source –Wizard191, CC BY-SA 3.0, via Wikimedia Commons

Step 1:

This is accomplished by pressing the faces into contact keeping them perpendicular such that it appears as a cross from the top.

Step 2:

And then imparting a small twisting motion whilst maintaining the contact pressure. The contact pressure is just sufficient in order to hold the two slip gauges in contact and no additional intentional pressure.

Step 3:

It is found that the phenomenon of wringing occurs due to molecular adhesion between a liquid film (whose thickness may be between 6 to 7 x 10-6 mm) and the mating surfaces.

When two gauges are wrung together and the overall dimension of a pile made of two or more blocks so joined is exactly the sum of the constituent gauges.

It is on the property of wringing units together for building up combinations that the success of the system depends, since by combining gauges selected from a suitably arranged combination, almost any dimension may be built up.

The accuracy of micrometers, vernier calipers, dial indicators can be checked by a slip gauge

These may be used as reference standards for transferring the dimensions of the unit of length from the primary standard to gauge blocks of lower accuracy, and for the verification and graduation of measuring apparatus, as well as length measures for the regulation and adjustment of

indicating measuring apparatus and for direct measurement of linear dimensions of the industrial component.

Grades or classes of slip gauges

There are five grades or classes of slip gauges:

#1. Grade 2

This is the workshop grade. Typical uses include setting up machine tools, positioning milling cutters, and checking mechanical widths.

#2. Grade 1

Used for more precise work, such as that carried out in a good-class toolroom. Typical uses include setting up sine bars and sine tables, checking gap gauges, and setting dial test indicators to zero.

#3. Grade 0

This grade is used in a confined toolroom or for machine shop inspection.

This means that it is the Inspection Department only that has access to this grade of slips.

In this way, it is not possible for these slip gauges to be damaged or abused by the rough usage to be expected on the shop floor.

#4. Grade 00

Grade 00 also known as inspection grade is kept in the Standard Room and for work of the highest precision only.

A typical example would be the determination of any errors present in the workshop or Grade 2 slips, occasioned by rough or continual usage.

#5. Calibration grade

This is a special grade, with the actual sizes of the slips stated or calibrated on a special chart supplied with the set.

This chart must be consulted when making up a dimension, and because these slips are not made to specific or set tolerances, they are not as expensive as the Grade 00.

It must be remembered that a slip gauge, like any other engineering component, cannot be made to an exact size.

All slip gauges must have tolerances on the length, flatness, and parallelism of measuring faces.

Except for the calibration grade, all slip gauge sets are manufactured to within specified limits; the closer the limits the more expensive the slip gauges, but in the case of the calibration grade, greater tolerances on length are permissible.

Because the actual lengths are known or recorded in the calibration chart, due allowance can be made when the slips are used.

Many times to reduce wear on inspection workshop grades a pair of protector gauge blocks (1 to 1.5 or 2 mm length) are also supplied and these are wrung to the end of the slip gauge combination block.

As these are made of tungsten carbide or similar wear-resisting material these do not wear out and protect the slip gauges from wear. These are marked with the letter ‘P on one measuring face.

Applications of slip gauges

(a) Reference standards for transferring the dimension of the unit of length from the primary standard to gauge blocks of lower accuracy and for the verification and graduation of measuring apparatus.

(b) Length measures for the regulation and adjustment of indicating measuring apparatus and for the direct measurement of linear dimensions of industrial components.

![37 Must Have Workshop Tools & Their Uses with [PDF & Images]](https://mechanicalpost.site/wp-content/uploads/2023/07/tool-stoarge.webp)

Excellent article, Wonderful points you have mentioned here. This was an awesome and helpful article. It is useful and helpful for me.

Keep sharing your valuable thought,