5-Axis CNC Machine: its working, types, uses & benefits

Introduction:

Have you ever wondered how manufacturers produce intricate and complex components with utmost precision? How do they achieve the seamless curves, sculpted surfaces, and geometric intricacies that seem almost impossible to create with traditional machining methods? The answer lies in the revolutionary world of especially the 5-axis CNC machines – the pinnacle of precision engineering.

When it comes to high precision CNC machines, 5-axis CNC machining is the go to choice. In this technical article, we’ll explore what is a 5 axis CNC machine and how does it work? its types, advantages, and applications.

So before we begin, learn about 3, 4, 5 and 6 Axis CNC machines where we discuss in detail about the various CNC axes, their advantages, limitations and differences between them.

Whether you are a seasoned CNC professional seeking to expand your horizons or an enthusiast eager to grasp the cutting-edge technologies of modern manufacturing, this article aims to fulfil your curiosity and unveil the untapped potential of 5-axis CNC machines.

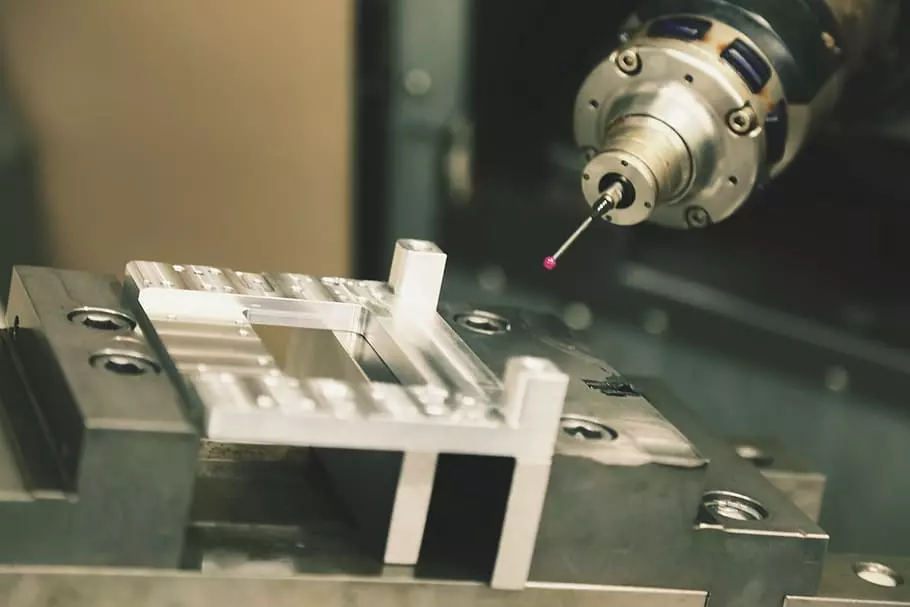

What is a 5-Axis CNC Machine?

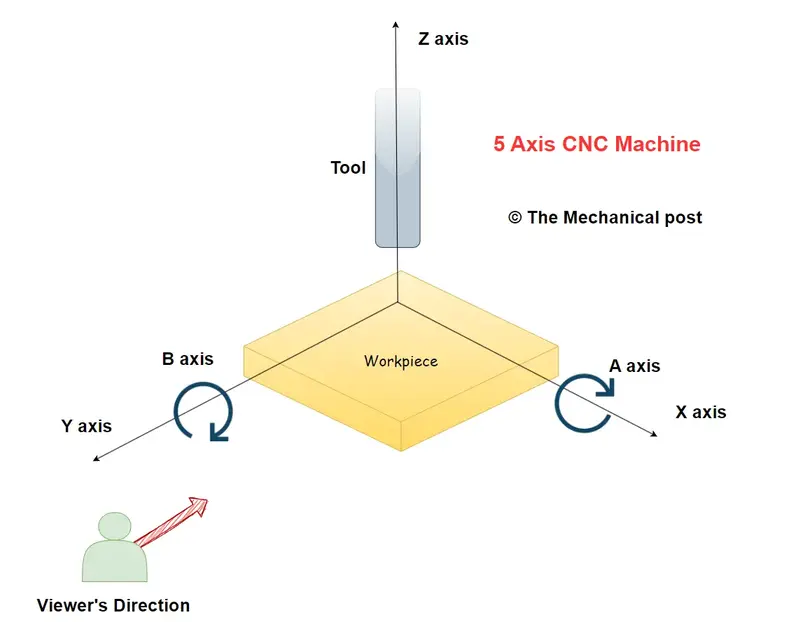

A 5-axis CNC machine has the 3 linear axes (X, Y, and Z) that provide motion in 3D space, plus 2 additional rotational axes that tilt and pivot the cutting tool.

The conventional 3 axes on a CNC machine allow the cutting tool to move linearly in these directions:

- X axis – left to right movement across the machine bed

- Y axis – front to back movement across the machine bed

- Z axis – up and down movement

A 5-axis machine adds two more axes:

- A axis – rotates the cutting tool around the X axis (tilts side to side)

- B axis – rotates the cutting tool around the Y axis (tilts front and back)

This gives the cutting tool much greater freedom of movement beyond just the linear X, Y and Z motions. The tool can be oriented at complex angles and approach the workpiece from any direction.

The two rotational axes may be configured on the workpiece, the spindle head, or both. Different configurations have their own advantages depending on the application.

How Does 5-Axis CNC Machining Work?

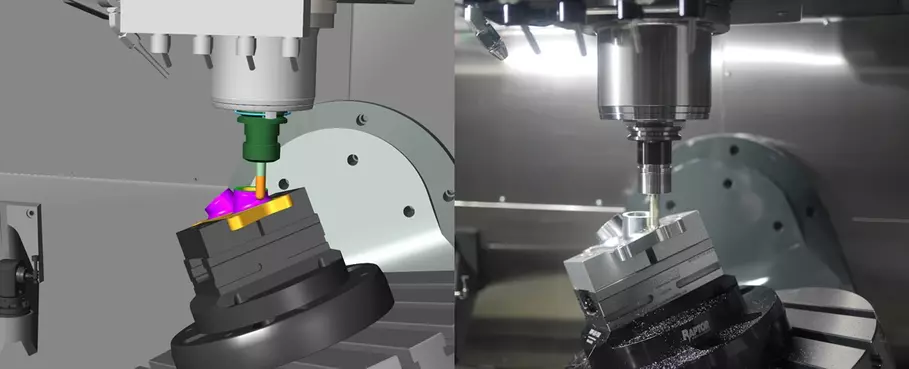

The basic methodology of 5-axis CNC machining is similar to conventional 3-axis machining. The main difference lies in the ability to orient the cutting tool at complex angles and reach difficult geometries by interpolating motion along the two rotary axes simultaneously with the linear X, Y, Z motions.

The typical workflow for 5-axis CNC machining is:

- Import CAD model: The solid model geometry is imported into the CAM software and oriented appropriately for machining.

- Toolpath programming: The CAM software slices the model into layers and generates appropriate toolpaths (contour parallel, raster, zig-zag etc.) based on the stock material, tooling, and finished shape. The toolpaths will incorporate motion along all 5 axes.

- Simulation: The toolpaths are visually simulated to detect any collisions, gouges, or interferences. The programs are optimized if needed.

- Set up: The workpiece is securely fixtured and the machine, tools, and offsets are set up.

- Machining: The pre-processed G-code program is executed on the 5-axis CNC machine. The cutting tool follows the contour toolpath with precise linear and tilt/rotary interpolation to shape the material.

- Verification: The machined part is measured to verify tolerances. If needed, additional semi-finishing, finishing or gouge clean up toolpaths are run.

With coordinated motion along the 5 axes, even extremely complex parts with organic, free-form surfaces can be machined efficiently.

Recommended for you: List of G code and M code for CNC Machines

Types of 5-Axis CNC Machines

There are several common configurations of 5-axis CNC machines available:

1. Table-Table Configuration

- Both rotary A and B axes are located in the table. Thus the table can tilt as well as rotate.

- The spindle head remains stationary

- Provides good undercut machining capabilities due to wide tilt ranges (e.g. 110 degrees)

- Offers largest usable work envelope as table can be tilted independently

- Suited for heavy material removal due to high spindle torque

- Limited to smaller workpieces that fit between table risers

- Heavier workpieces have a limitation as the table has to tilt or rotate for machining to happen, as compared to of the tool moving around the workpiece in other 5 axis configurations

2. Head-Table Configuration

- One rotary axis on spindle head, one rotary axis on table

- Allows heavier workpieces as table doesn’t tilt, it only rotates.

- Rigid setup transfers weight directly to machine base, hence heavier parts can be machined.

- Shorter tools can be used as head articulates over part

- Versatile for both 3-axis and 5-axis machining

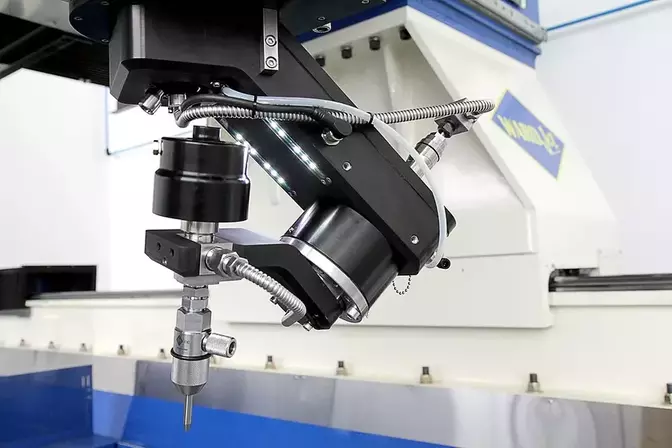

3. Head-Head Configuration

5 axis Water jet CNC, source: WARDJet, CC BY-SA 2.0, via Wikimedia Commons

- All rotations performed by the machine spindle head, the worktable remains stationary

- Stationary table provides rigid setup for heavy parts

- Variety of part sizes can be machined

- Requires specialized tooling to avoid collisions

So to sum it up, Table-Table machines offer undercut access but limited work envelope, Head-Table allows heavy and modular machining, while Head-Head specializes in large 5-axis workpieces. The optimal configuration depends on the specific application requirements.

Benefits and Advantages of 5-Axis Machining

Compared to conventional 3-axis CNC machining, 5-axis machining offers many significant benefits:

- Greater Flexibility

- Improved Machining Efficiency

- Higher part accuracy and quality

- Ability to produce complex surfaces

- Ability to Approach Features from Any Angle

- Reduced Material Waste

- Faster Time-to-Market

1. Greater Flexibility

The two additional rotational axes offer a whole new dimension of tool positioning flexibility. The tool can be manipulated into complex orientations, enabling machining of intricate contours, undercuts, cavities and 3D geometries that are completely inaccessible with just 3 axes.

2. Improved Machining Efficiency

Parts that require multiple setups and reorientations on a 3-axis machine can be machined efficiently in a single setup on a 5-axis machine. The tool constantly maintains optimal engagement with the changing workpiece geometries, minimizing air cutting and cycle times.

3. Higher Part Accuracy and Quality

The tool tip can be precisely positioned and controlled in 5 dimensions for greater accuracy. This allows machining parts to tighter tolerances and better surface finish quality. The optimized tool paths also maximize tool life.

4. Ability to Produce Complex Surfaces

The simultaneous motion along the 5 axes enables machining of any complex contour or shape, including sculptured, organic and free-form surfaces. This is useful for automotive, aerospace, medical and other applications.

5. Ability to Approach Features from Any Angle

With full orientation capability, the tool can approach features from any direction rather than just orthogonal 3-axis angles. Internal features and geometry otherwise inaccessible can now be machined from the optimum angle.

6. Reduced Material Waste

Machining from multiple angles leaves no remaining inaccessible material and minimizes scrapped components. This reduces overall material costs and waste.

7. Faster Time-to-Market

By efficiently machining complex parts in a single setup, 5-axis machining greatly reduces manufacturing times compared to conventional multi-step processes using traditional machines like Lathe machine etc. This enables faster product development cycles and market delivery.

Limitations of 5-Axis Machining

While offering many benefits, 5-axis CNC machining also has some limitations:

- Higher Machine Costs

- Advanced Programming skills

- Difficult Setups and Calibration

- Lower Material Removal Rates

- Requires Skilled Operators

- Not Ideal for High Volume Production

1. Higher Machine Costs

The additional axes, sophisticated controls, and associated components add cost and complexity. 5-axis machines are a bigger investment than 3-axis machines.

2. Advanced programming skills

Generating efficient 5-axis toolpath requires more advanced CAM software and programming skills. Avoiding collisions while fully utilizing the work envelope is difficult.

3. Difficult Setups and Calibration

Workpiece loading and fixturing can be challenging to avoid collisions and maintain accuracy. Comprehensive calibration and frequent maintenance is required.

4. Lower Material Removal Rates

While more efficient for finishing operations, the flexible 5-axis motion cannot match the high feed rates possible during roughing on 3-axis machines.

5. Requires Skilled Operators

Specialized expertise is required for programming, setup, operation, and maintenance. Extensive training is needed to utilize 5-axis capabilities fully.

6. Not Ideal for High Volume Production

The highly complex programming and setup makes 5-axis most suitable for low to medium production batches rather than mass production.

Applications/uses of 5-Axis Machining

Some common applications taking advantage of 5-axis CNC machining include:

Aerospace

Machining intricate aerospace structural and engine components with complex curves and internal features from hard-to-machine alloys.

Automotive

Producing automotive molds, dies, prototypes and parts with highly complex sculpted surfaces and tight tolerances.

Medical

Machining medical implants like artificial joints, sculptures, and dental restorations requiring very high precision.

Tooling and Mold Making

Efficient machining of molds, dies and tooling with complex cooling channels and moving/sliding components.

Turbine Blades

Machining intricate turbine blade airfoils with complex internal geometry, cooling holes and channels.

Impellers

Producing impellers with complex double curvature blade geometry and 5-axis undercuts.

Prototyping

Rapidly machining functional prototypes directly from CAD requiring complex surfacing and shapes.

Frequently Asked Questions regarding 5 axis CNC machine:

Some questions that might have come to you while reading this article, worry not we’ve got you covered with some frequently asked questions.

How many axes does a 5-axis machine have?

5-axis machines have two additional rotary axes (A and B) beyond the conventional X, Y and Z linear axes, for full 5-axis motion.

.

What can you do with 5 axes that you can’t with 3?

The two extra rotational axes provide complete tool orientation flexibility to machine complex contours, undercuts, cavities, and curved surfaces in ways impossible on 3-axis machines.

.

What materials are machined on 5-axis CNCs?

5-axis machining is predominantly used for harder materials like steel, aluminum, titanium and other alloys. But it also supports plastics, wood, foam, wax and other softer materials.

.

When should 5-axis machining be used instead of 3-axis?

5-axis is required where optimal tool orientation is critical for efficiency or part geometry is too complex for 3-axis machines. It reduces setups and expands design possibilities.

.

What CAM software is needed for 5-axis machining?

Advanced CAM software like CATIA, Siemens NX CAM, Mastercam, or ESPRIT is needed for the complex toolpath calculations and precise post-processing required to fully utilize 5 axes.

.

Who uses 5-axis CNC machines?

The automotive, aerospace, medical, tooling/mold, turbine, electronics and other advanced manufacturing industries use 5-axis for accuracy, speed, flexibility and the ability to produce complex geometries.

.

What are some downsides of 5-axis machining?

The main downsides are higher machine costs, challenging programming, longer setup times, specialized skills needed, and lower material removal rates compared to 3-axis high speed machining.

.

How accurate is 5-axis CNC machining?

With proper calibration, speed/feed control and use of ball nose cutters, accuracy within 0.005” is achievable. Precision can reach 0.0005” for micromachining applications.

.

Can 5-axis CNC do contouring?

Yes, the excellent tool orientation control makes 5-axis CNC ideal for machining continuous complex contours, sculpted shapes, and other nonlinear surfaces.

.

Conclusion

5-axis CNC machining offers tremendous benefits in flexibility, accuracy, efficiency and the ability to produce highly complex part geometries with tighter tolerances. While requiring greater expertise and costs, the performance gains allow machining of components previously impossible or very difficult to manufacture. With skilled programming and application, 5-axis CNC machines greatly expand the design possibilities and manufacturing capabilities for critical industries.