Difference between Centrifugal pump and Reciprocating pump with PDF

Pumps are being used for a variety of applications be it in your automobile to the ones being used for industrial applications.

Out of them, centrifugal and reciprocating pumps are the most common names. Also as, a Mechanical engineer, you must have come across the words “Centrifugal pump” and “Reciprocating pump” a number of times.

Have you ever wondered, what is the difference between a centrifugal pump and a reciprocating pump? This is exactly what we are going to answer in today’s article.

Get your Free copy of the PDF on the difference between a centrifugal pump and a reciprocating pump at the end of this article.

Before we look at the differences between the two pumps, let us understand both of them in brief.

What is a Centrifugal pump?

A centrifugal pump is a pump in which an impeller (propeller) rotates inside a closed casing draws in liquid at the center, and by virtue of centrifugal force, throws out through an opening to the delivery pipe.

It makes use of the centrifugal force created by the rotating impeller to impart kinetic energy to the liquid. The casing of the pump then converts the kinetic energy of the liquid into pressure energy. This is how we get pressurized liquid

Applications of centrifugal pumps include:

- Centrifugal pumps are used in hydraulic control circuits.

- In buildings to pump the water to the tank at the top.

- They are used in sewage and drainage systems.

- In water purification plants.

- They are also used in beverage industries.

- In chemical industries.

Advantages of Centrifugal pump include:

- The Centrifugal pump is simple in design.

- It has a high discharge rate.

- No shocks during operation.

- It has low maintenance.

We have a detailed article on Centrifugal pumps, their construction, working, and much more which you can check out here.

What is a Reciprocating pump?

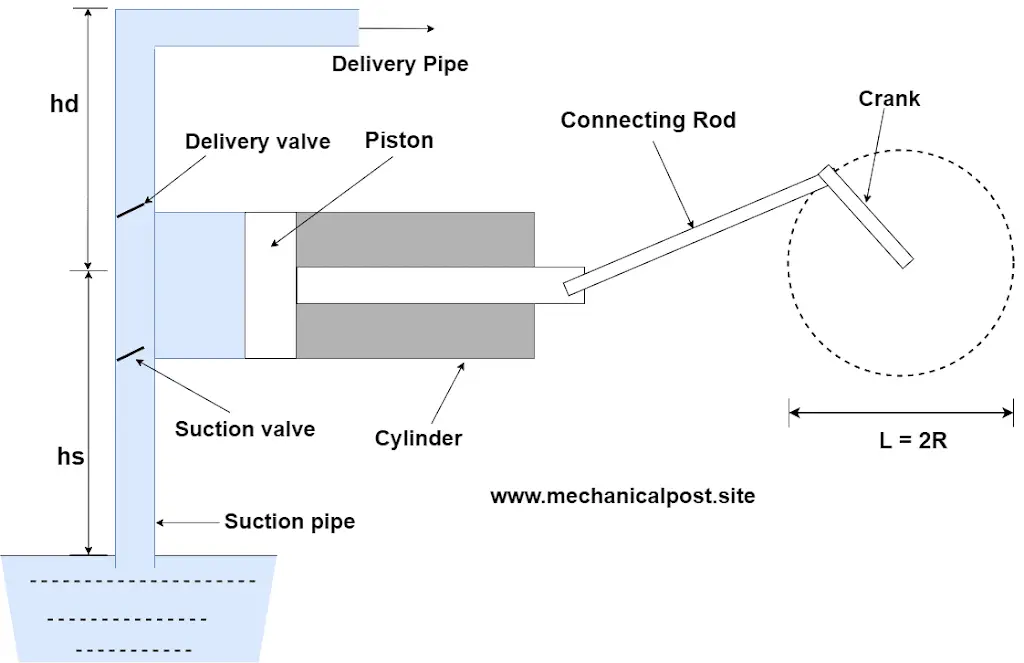

A reciprocating pump is a pump with a piston-cylinder arrangement. The piston reciprocates within an enclosed cylinder and hence the name “reciprocating pump”.

A motor provides reciprocating motion to the piston with the help of a crank and connecting rod. As the piston moves backward, it creates suction which causes the liquid to enter and fill the cylinder. Now when the piston moves forward, the piston pushes the liquid.

Since the liquid has no way to go except the outlet, the pressure of the liquid increases drastically due to the forward stroke of the piston. And this is how pressurized liquid is obtained.

Applications of reciprocating pump include:

- A reciprocating pump is used in hydraulic jacks.

- Pumping of fluids at high pressures in industries.

- Reciprocating pumps are used in boilers where high pressure is required.

- It is used in oil refineries and petroleum industries.

Advantages of Reciprocating pump:

- In a reciprocating pump, very high pressure can be achieved.

- No priming is required.

- Reciprocating pumps require less starting torque.

Check out in-depth about reciprocating pumps, their parts, working, calculation, etc, here.

Difference between a Centrifugal pump and Reciprocating pump

| Reciprocating Pump | Centrifugal pump |

|---|---|

| Reciprocating pumps have a piston-cylinder arrangement, in which the piston pressurizes the liquid. | Centrifugal pumps have an impeller enclosed in the casing that rotates at a high r.p.m in order to produce pressurized liquid. |

| Reciprocating pumps are low discharge pumps. | Centrifugal pumps have a high discharge rate. |

| Reciprocating pumps are used where high pressure is required. | Centrifugal pumps are suitable for low to medium pressure applications |

| It does not require priming i.e they are self-priming. | It requires priming for operating. |

| Reciprocating pumps are also known as “Positive displacement pumps” | Centrifugal pumps are also known as “Dynamic pumps” |

| They require more floor area. | They are small and compact as compared to reciprocating pumps. |

| Due to more moving parts, there is increased wear and tear, thus resulting in increased maintenance as compared to centrifugal pumps. | Due to less wear and tear the centrifugal pump needs less maintenance. |

| Reciprocating pumps have high efficiency than centrifugal pumps. | Centrifugal pumps have a lower efficiency. |

| They are heavy in weight. | They are light in weight. |

| Non-return valves are used in reciprocating pumps at the inlet and outlet. | No non-return valves are not required. |

| Reciprocating pumps are costly. | Centrifugal pumps are inexpensive as compared to reciprocating pumps. |

| Applications of reciprocating pumps include oil refineries, petroleum industries, high-pressure boilers like LaMont boilers in steam power plants, etc. | Applications of centrifugal pumps include sewage systems, to pump water in buildings, in chemical industries, etc. |

That’s all about the Difference between Centrifugal and Reciprocating pumps. If you find this article helpful do let us know in the comments.

Also, do join our Telegram Channel @TheMechanicalpost

We’ll be back with another informative and interesting article, till then Keep Learning!