What is a cotter joint? Its parts, types, advantages & uses with PDF

The most used joint to join two bodies undergoing compressive or tensile axial force is a cotter joint. It has been around for quite some time and can be noticed during applications in many different fields. The first cotter joint is estimated to be built around the 1800s in Germany.

Which was back then being used by farmers for their cart wagons. The word ‘cottar’ is used in regions of Scotland and Ireland to describe a farmer or someone who takes a cottage. Thus inspiring the word cotter.

This article shall give you some good insights about a cotter joint, its types, applications, advantages, and limitations. Also, you can download the FREE PDF on the cotter joint at the end of the article.

What is a joint?

A joint is any part of a machine dedicated to connecting one or more mechanical parts together.

They usually attract engineers because of their high strength capacity. Joints are classified as temporary or permanent based on their nature. Certain joints can be dismantled and thus are called temporary joints. They provide a huge benefit with respect to the maintenance of the machines and are thus used extensively in heavy-duty machines, it also provides more freedom with respect to the choice of material.

Joints are usually application specific.

What is a Cotter joint?

A cotter joint is a mechanism, used to join two co-axial rods while undergoing axial force (both compressive and tensile), it can also be used to join a rod with some machine parts like a base plate.

Cotter’s joints are used in applications where we have axial loads which are either pure compressive or pure tensile or have both compressive and tensile forces with minimum or negligible radial forces

A cotter joint is only applicable in cases of no rotation or radial force and co-axial rods. Its performance is also characterized by the shape of the rod and in certain applications is capable of undergoing very high axial forces due to heavy-duty machinery.

The principle on which the cotter joint works is wedging wherein the tapering of the cotter induces friction to be very high and thus prevents the assembly from loosening even in cases of high axial forces.

This makes friction very crucial in a cotter joint, especially around the cotter and thus the accuracy of the cotter and the slots affect the performance of the assembly significantly.

Yet, the material used for the spigot and socket is often stronger or equally strong as that of the cotter. This is because the cotter is easily replaceable but the spigot and socket are difficult to manufacture comparatively and thus would be more economical losses.

Parts of a cotter joint

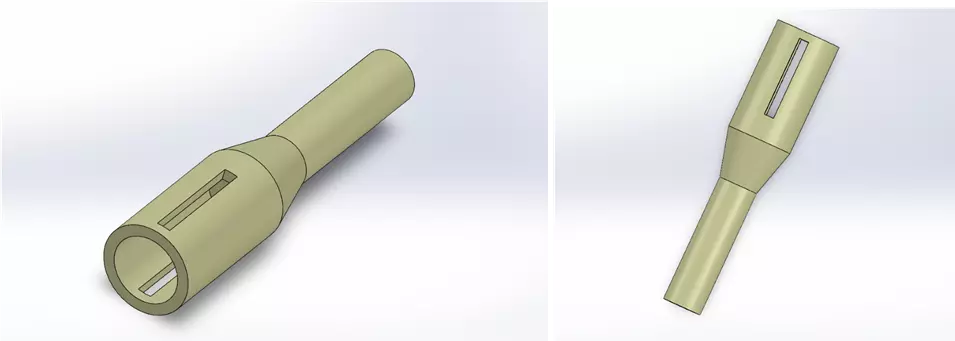

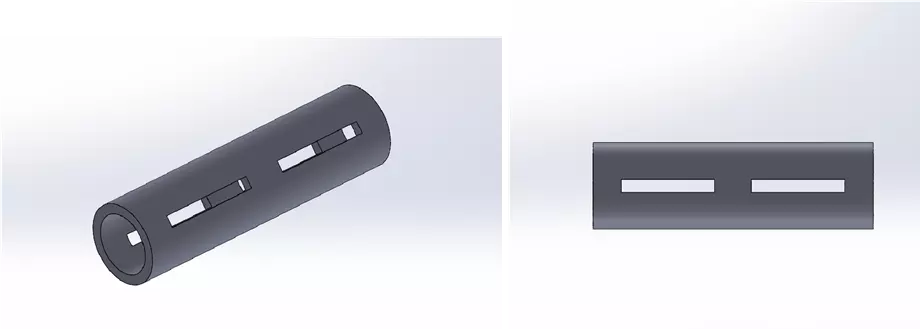

Socket.

It is an extension to a rod attached, it is hollow and can be used to allow the spigot end of the other rod to go inside. It is designed with a rectangular slot for the cotter to go in. The inner diameter of the majority of the socket is equal to the outer diameter of the spigot.

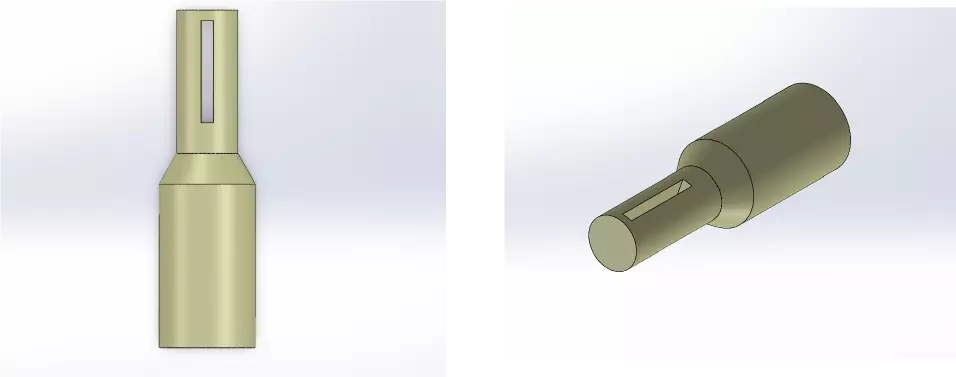

Spigot.

It is an extension provided to a rod, the spigot goes inside the socket and is designed to occupy most of the volume, just like the socket even the spigot has a rectangular slot for the cotter to go in.

Sleeve.

It is a type of socket which is not attached to a rod and can be plugged in from both sides with spigots. Since it has two spigots, it also has two slots, as a separate cotter is used for each spigot. The inner diameter of the majority of the sleeve is equal to the outer diameter of the spigot.

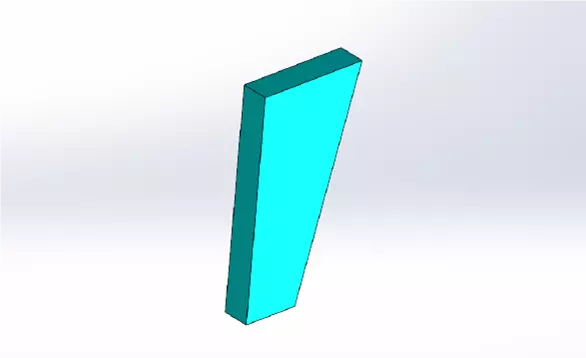

Cotter.

It is the most crucial element of the mechanism, a tapering rectangle that goes inside the spigot and the socket to lock them using wedge action and ensure that they are attached to each other. An assembly is complete only when the cotter goes through both, the slots in the spigot and the socket. We only need to remove the cotter to dismantle this assembly.

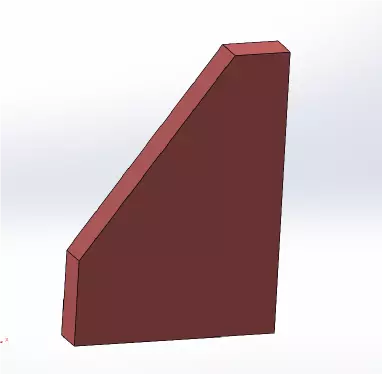

Gib.

In certain assemblies, to prevent slotting the rod in a tapered manner, a gib is used which has one side tapered in such a way that it cushions the cotter.

Types of a Cotter joint:

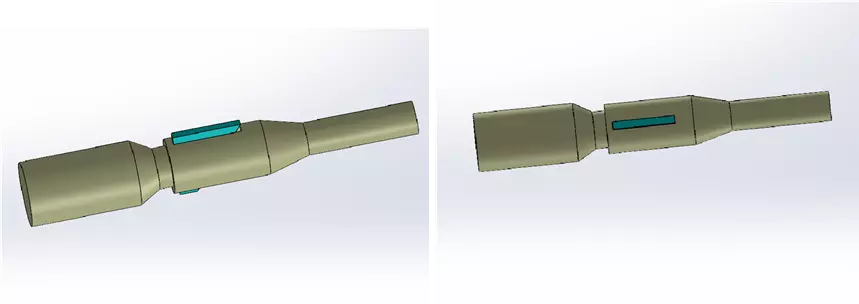

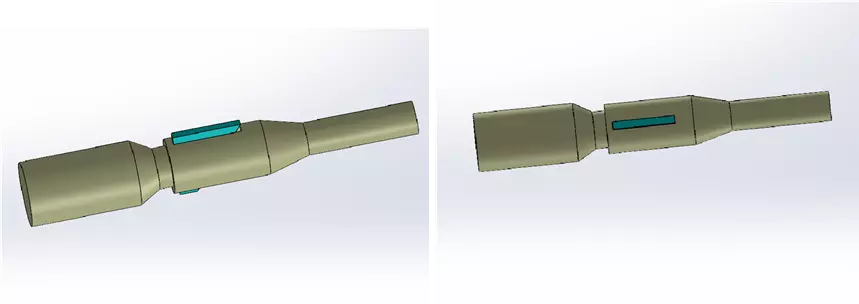

#1. Socket and Spigot Cotter joint.

It is the traditional Cotter joint in which one of the two rods has a socket attached to it and the other has a spigot attached to it.

The cotter goes through the slots provided in both the spigot and the socket to make it assembled. While dismantling it the cotter has to be removed and the spigot pulled out.

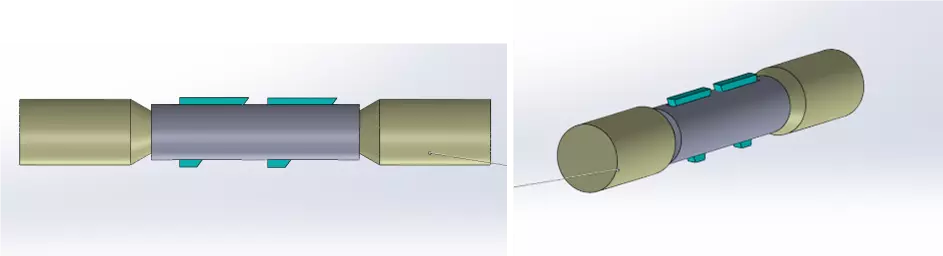

#2. Sleeve and Cotter joint.

In this type, the attached socket is replaced by a sleeve that is not attached to a rod. The sleeve has the same function as that of the socket. Both the rods have an attached spigot and go inside the sleeve from opposite ends, each one of the rods is then attached to the sleeve with a cotter of its own. Due to this, we need two cotters in the assembly.

The cotter goes through the slot in the spigots and the sleeve to make it assembled. While dismantling the assembly both the cotters have to be removed and then both the spigots are to be pulled out.

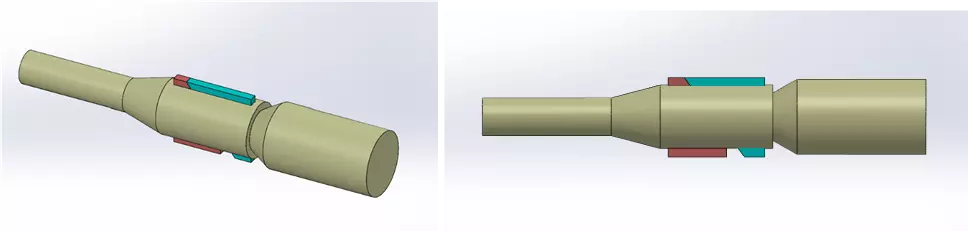

#3. Gib and Cotter joint.

In certain assemblies, usually, ones with square rods, a tapered slot on the spigot end or the socket are not doable, which is when a gib is used. This gib has only one side tapered and the other is vertical, the tapered end of the gib is used to match the tapered end of the cotter in such a way that we do not need to make any tapered slots.

The cotter along with the gib goes through the slots provided in the sleeve or the socket as well as the spigot. While dismantling the gib and cotter both are to be removed from the sleeve or the socket and then the spigots are to be pulled out.

Recommended for you:

- Knuckle Joint: its parts, applications and advantages

- Gear Terminology

- What are the Different types of gears?

- Types of couplings and their uses with PDF

Advantages of a Cotter joint

1) Ease in assembly.

The cotter joint is very simple and straightforward when it comes to assembly, with the cotter being the most crucial component and the condition of it to pass from slots provided in both the spigot and the socket.

2) High strength capacity.

The cotter joint enhances the ability of a machine to undergo axial load significantly and is thus used in many heavy-duty types of machinery.

3) Applicable for all shapes of the rod.

A cotter joint is applicable with triangular, circular, and even square shapes. Most of its applications are in circular and rectangular rods as its performance is heavily affected by the shape and symmetry of the rod.

4) Ability to undergo tensile and compressive loads.

Its ability to withstand both tensile and compressive loads makes it very attractive for machines undergoing motion.

5) Manufacturability.

The parts that are used in a cotter joint are very simple to be manufactured. The parts can also be found in various marketplaces very conveniently.

6) Rigidity.

After the assembly is done, the entire joint is completely rigid and undergoes negligible relative motion.

Limitations of a Cotter joint

1) Inefficient with radial loads:

The cotter joint is used in times of minor or negligible radial forces and thus is inefficient in cases where the radial forces are high.

2) Accuracy of the cotter.

The cotter is very critical and is thus supposed to be very accurately built, the performance of the joint heavily depends on the accuracy of the cotter manufactured.

3) Inapplicable with rotation.

The cotter joint is very inefficient when it comes to rotation due to the radial forces induced due to it (Centripetal and Centrifugal forces) and thus in cases of rotation and many torque-driven applications, we cannot use a cotter joint.

4) Low performance with dissimilarities.

The cotter joint is heavily affected by dissimilarities and symmetric shapes are thereby preferred while using a cotter joint.

5) Co-axial rods.

A Cotter joint can only and only be used in cases where the two rods are co-axial, thus we cannot use a cotter joint in various applications that have non-co-axial rods

Applications of a Cotter joint

1. Foundation Bolt. A Foundation bolt is a type of cotter joint which is used in many applications to fasten the foundation with construction heavy machines.

2. Automobile engines. A cotter joint is used to connect the piston rod to the crosshead of an engine

3. Valve mechanism. In the valve mechanism, the fork is connected to the slide spindle by the use of a cotter joint

4. Steam engines. A cotter joint is used in connection with a connecting rod in the steam engines

5. Flywheel. The Cotter joint along with Dowell’s joint is used to join two parts in a flywheel.

6. Wet air pump. It is used to connect the tail rod with the piston rod in a wet air pump.

7. Bicycles. It is used in bicycles to connect the sprocket wheels with the pedals.

That’s all about the Cotter joint, its parts, assembly, advantages, limitations, and applications. Also, do share this article with your fellow engineers so that they too can benefit from this.

We’ll be back, until then Keep Learning!