The Free to use Knuckle Joint Design Calculator by The Mechanical post is a powerful and user-friendly web-based tool that facilitates the efficient and accurate design of knuckle joints, a widely used mechanical joint configuration for students and professionals.

Knuckle Joint Design Calculator

Design of Knuckle Joint

A knuckle joint is used to connect two rods which are under tensile load when a small amount of flexibility or angular movement is required. The joint consists of a single eye, double eye, and knuckle pin. This post will cover the design procedure and important formulas of knuckle joint for sizing the components of a knuckle joint.

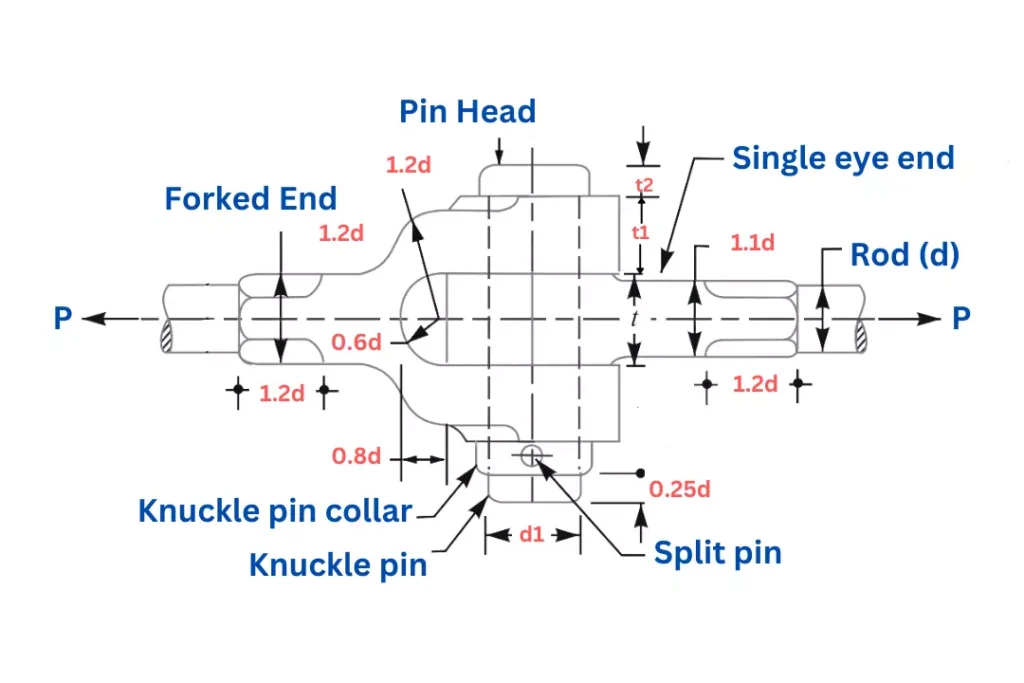

Parts of a Knuckle Joint

- Single eye: Formed at one end of the rod

- Double eye (fork): Formed at the other end to fit over single eye

- Knuckle pin: Joins the single eye and fork, with head on one end

Design Procedure

The design involves determining the dimensions of the rod, pin, eyes and fork based on the tensile load on the joint and material strengths.

1. Diameter of Rod

The diameter of the rod can be calculated based on the applied tensile load and the permissible tensile stress of the rod material:

d = √(P/(π/4*σt))

Where:

d = Diameter of rod

P = Tensile load

σt = Allowable tensile stress

2. Diameter of Knuckle Pin

The knuckle pin diameter is calculated based on the shear and bending stresses.

Shear stress:

d1 = √(P/(2*τ*π))

Where:

d1 = Diameter of knuckle pin

P = Tensile load

τ = Allowable shear stress

Bending stress:

d1 = ((32*P*(t1-t2))/(π*σb))^(1/3)

Where:

t1 = Thickness of fork

t2 = Thickness of pin head

σb = Allowable bending stress

Note: The larger value of d1 from the above two formulas is taken.

3. Dimensions of Eyes and Fork

Empirical relations are used to calculate the remaining dimensions:

d2 = 2*d d3 = 1.5*d t = 1.25*d t1 = 1.75*d t2 = 0.5*d

Where:

d2 = Outer diameter of eye

d3 = Diameter of pin head

t = Thickness of single eye

t1 = Thickness of fork

t2 = Thickness of pin head

4. Design Checks

The final design should be checked for the following failure modes:

- Tensile failure of rod

- Shear failure of pin

- Bending failure of pin

- Tensile failure of single eye

- Shear failure of single eye

- Crushing failure of single eye

- Tensile failure of fork end

- Shear failure of fork end

- Crushing failure of fork end

Learn more in detail about Knuckle joint, its construction, applications, advantages and limitations

By following the design procedure of knuckle joint and checking all the failure modes, a safe and optimal design of the knuckle joint can be obtained. The important takeaway are the formulas for calculating the rod diameter, pin diameter and other dimensions based on strength criteria.