What is a knuckle joint? its parts, working, advantages and uses.

Do you know what a link of roller chain, robotic arms, and tie rod of roof truss have in common? They all have knuckle joints.

This is The Mechanical post and today you would be reading about What is a knuckle joint? its construction, advantages, disadvantages, and applications.

Get your copy of the PDF on the Knuckle joint at the end of the article.

What is a knuckle joint?

A knuckle joint is a temporary joint used to connect 2 rods subjected to tensile loads. The joint permits angular misalignment between the rods in the same plane.

A knuckle joint is also called a “Forked pin joint”.

Knuckle joints are capable of taking large tensile loads. However, it cannot withstand large compressive loads. Unlike couplings, a knuckle joint cannot transmit torque.

Must Read: Different types of Couplings with PDF

Parts of the Knuckle joint

Construction and working of Knuckle joint

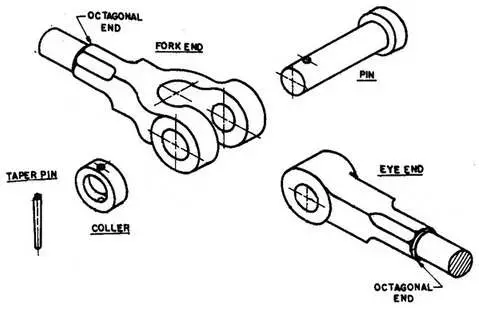

The end of one rod which is to be connected is made into a fork shape and is also known as the Fork or Yoke or Double-eye end as shown in the figure.

One end of the rod which is to be connected is made into the fork shape. The other rod end is made into the single-eye end (the one with 1 hole).

The single eye is placed between the 2 eyes of the fork end such that all the 3 holes (i.e. 2 of the fork end and 1 of the single end) coincide.

A knuckle pin is used to connect the single eye and double eye together. The knuckle pin passes through the hole and connects them. It has a small hole in it at its end.

A collar is placed at the end of the knuckle pin such that the hole in the collar coincides with the hole in the knuckle pin.

A tapered pin is passed through the holes to secure the collar & knuckle pin and prevents them from sliding off.

This is how the knuckle joint is formed.

Want to Design the Knuckle Joint ? Check out our FREE Knuckle joint Design Calculator with steps and formulae.

Advantages of Knuckle joint

- Knuckle joint can be easily assembled & dismantled.

- The design is simple.

- It is easy to manufacture.

- It can endure large tensile loads.

- Knuckle joints have good mechanical rigidity.

- It permits angular movement between the 2 rods.

Limitations of Knuckle joint

- The knuckle joint cannot hold up against a large compressive load.

- It is not as flexible as a Universal joint.

- The angular movement is permitted in only one plane.

Applications of Knuckle joint

- To connect the trolley to the tractor.

- To connect tie rod of jib crane.

- Tension link in bridge structure

- Link of roller chain

- To connect the tie rod of a roof truss.

- To connect robotic arms.

FAQ’s on Knuckle joint

What is the difference between Cotter joint and knuckle joint?

The main difference between a cotter joint and a knuckle joint is that a cotter joint can withstand compressive as well as tensile loads, whereas, a knuckle joint can withstand tensile load only.

Also, a cotter joint does not permit angular movement between rods while a knuckle joint permits limited angular movement between the rods.

Which type of load can be transmitted by knuckle joint?

A knuckle joint is capable of transmitting large tensile loads. However, it cannot withstand large compressive loads.

Is a knuckle joint suitable for two rotating shafts which transmit torque?

A knuckle joint is not suitable for the transmission of torque between two rotating shafts.

That’s an overview of the Knuckle joint. Do share it with your fellow engineers with the social links provided below.

Till then Keep Learning!