Universal joint | assembly and details | The Mechanical post

In engineering applications many a times power or rotary motion is requried to be transmitted from one shaft to another shaft. However, it is easy to transmit motion if both the shafts are in same line, an oldham’s coupling can be used. But what if one shaft is at an angle? How to transmit the power? At this time the universal coupling or joint proves effective.

Construction of Universal joint.

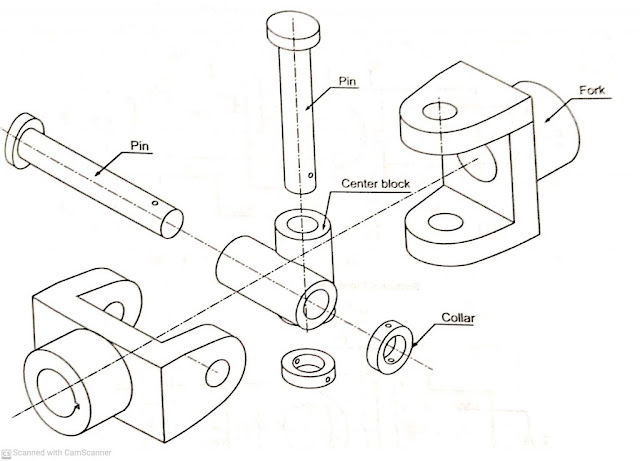

- The main parts of the universal joint are (Universal joint can be made up of steel or thermoplastic depending upon the usage) :

- Fork : It is the main connecting body which is connects the shaft to the centre block.

- Centre Block : It forms the heart of the universal joint. The centre block consists of two hollow cylinders placed 90 degrees apart to which all the parts of the universal joint are assembeled.

- Pin : Pins are the used to lock and keep all the components connected.

- Collar : It is used to prevent the pins to slip and holds it in place.

The assembly is done as shown in the above figure.The shafts used to transmit power are connected to the fork via a key on both ends.The forks are placed over the centre block and then pins are passed through the fork into the centre block.The emerging ends of the pins are sealed off with the collar.Thus, in this manner the assembly is completed

Applications of Universal joint.

- Aeroplanes.

- Automobiles

- Control mechanisms

- Textile machinery etc.