Ultrasonic machining: parts, working, uses, advantages with PDF

You must have heard of ultrasonic sensors, ultrasonic flowmeters, ultrasonic testing, and much more. Today we’ll see another type of non-traditional machining process called “Ultrasonic machining” also known as USM.

Download your PDF copy of Ultrasonic machining at the end of the article.

What is ultrasonic machining?

The ultrasonic machine process is a non-traditional machining process wherein a high-frequency tool vibrates against the workpiece material with an abrasive slurry in between them through a nozzle.

Unlike conventional machines like the CNC machine, the ultrasonic machining process is can be used for machining materials like ceramics, steel, precious stones, etc.

Working principle of Ultrasonic machining

The ultrasonic machining process operates on the principle that the ultrasonic vibration of the tool along with an abrasive slurry causes the machining of the workpiece through erosion of workpiece material.

The ultrasonic machining process is similar to the Abrasive jet machining process.

Construction of ultrasonic machining

- Power supply

- High-frequency generator

- Electro-mechanical transducer

- Ultrasonic amplitude transformer

- Tool holder

- Tool

- Abrasive slurry

- Pump

Power supply

The ultrasonic machining process requires a power supply of an Alternating current for its operation.

High-Frequency generator

The high-frequency generator increases the 50-60hz frequency of AC current to about frequency in the range of 20,000 to 40,000 Hz.

Electro-mechanical transducer

The electro-mechanical transducer receives the current from the high-frequency generator and converts it into mechanical vibrations.

The transducer works on the principle of “Magnetostriction”. The Magnestriction effect is that in which a material changes its dimension in response to an electric field.

Ultrasonic amplitude transformer

It is used to amplify the vibrations produced by the electro-mechanical transducer. It is also known as the “horn”.

Tool holder

At the end of the ultrasonic amplitude transformer, the tool holder is situated. As the name suggests, the tool holder holds the tool firmly in one place during operation.

Tool

The tool is made up of materials like stainless steel, mild steel etc. Also, the tool is in the shape of the cavity to be formed on the workpiece.

Abrasive slurry

An abrasive slurry is a mixture of abrasive particles like silicon carbide, alumina, or boron carbide mixed with either water or oil.

Due to the abrasive particles, the erosion of the workpiece material takes place.

Pump

A centrifugal pump is used to pump the abrasive slurry at desired a pressure onto the workpiece.

Working of Ultrasonic Machining process

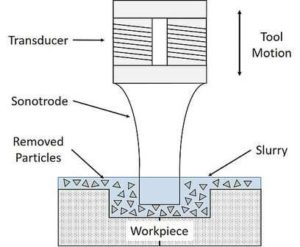

When the power supply is switched ON, the AC current flows through the high-frequency generator wherein the frequency is amplified to 20 kHz – 40 kHz.

|

| Source – Four30, CC BY-SA 4.0, via Wikimedia Commons |

This high-frequency AC current is passed on to the electro-mechanical transducer which converts the electric current into mechanical vibrations.

These vibrations are then amplified and transferred to the tool.

The abrasive slurry is continuously pumped between the tool and the workpiece.

The vibrations of the tool cause the abrasive slurry to impact the workpiece. Due to the abrasive action of the slurry, the workpiece is removed little by little.

This is how the Ultrasonic machining process works.

Check out this half a minute long animation video of the Ultrasonic machining process:

Advantages of ultrasonic machining

- Ultrasonic machining is capable of machining brittle materials.

- A good surface finish is obtained.

- It is highly accurate.

- Operation is economical.

- Both conducting and non-conducting materials can be used.

You might also like to read:

Limitations of ultrasonic machining.

- Ultrasonic machining consumes a lot of power.

- It has a low metal removal rate.

- Abrasive slurry has to be replaced periodically.

- High initial investment.

- The tool tip is subjective to wear and hence shorter life.

Applications of ultrasonic machining

- Ultrasonic machining is used to machine brittle materials.

- Grinding of brittle materials.

- Step drilling

- Drilling holes.

- Engraving.

- Producing fine and intricate shapes.

- Machining materials like tungsten, carbides, precious stones.

┅┅┅┅┅┅┅┅┅┅┅

That’s an overview of Ultrasonic machining. Do let us know your thoughts in the comments.

We’ll be back with another interesting article, till then keep learning!

![What is a Conveyor System? Its types, uses, advantages [with PDF]](https://mechanicalpost.site/wp-content/uploads/2022/02/What-is-conveyor-system.webp)

![What is Industrial Automation and its Types? [with PDF]](https://mechanicalpost.site/wp-content/uploads/2021/10/What-is-Industrial-Automation-ad-its-types.webp)