14 Differences Between Nuts And Bolts You Need To Know With PDF

Are you often confused about the terms “nuts” and “bolts”? In this blog post, explain these two essential fasteners and explore their key differences. Whether you’re a DIY enthusiast or a seasoned engineer, understanding nuts and bolts is crucial for various projects. Let’s dive in and discover what sets these hardware components apart!

Nuts and bolts are two of the most fundamental components used in engineering and manufacturing applications. Both nuts and bolts are threaded fasteners, meaning they use threaded shafts to secure objects together. However, there are some distinct differences between nuts and bolts and how they function.

In this in-depth guide, we will cover everything you need to know about the differences between nuts and bolts. We will define what nuts and bolts are, compare their properties in a table, and provide a detailed FAQ section to answer common questions. Whether you are an engineer, machinist, auto mechanic, or DIYer, this article will help explain the unique attributes of nuts versus bolts.

Be it simple machines to Complex highly advanced machines like the 5-axis CNC machines you’ll find nuts and bolts holding up your machine together.

Also as always get a FREE downloadable PDF on difference between nuts and bolts at the end of the article!

What is a Nut?

A nut is a fastener component that contains internal (female) threads and is used with bolts to securely join materials. Nuts provide a compressive holding force when tightened against parts being fastened together.

Some key properties of nuts include:

- Internally threaded hole through center

- Flat shape, typically hexagonal or square

- Threads run fully through interior hole

- Made of metal but also nylon, plastic, or other materials

- Tightened with wrenches, pliers, or tools onto bolt threads

- Stationary when tightened – bolt rotates

- Available in different sizes, threads, and strengths

- Used with matching bolts of same thread pitch and diameter

There are many types of nuts such as hex nuts, wing nuts, flange nuts, lock nuts, and more that serve varied fastening needs. Overall, nuts are versatile, reusable fasteners that form half of the essential nut and bolt system used universally in construction, machines, and manufactured products.

Learn More about the Different types of screw threads, like square, buttress, V-thread etc, and where they are used?

What is a Bolt?

A bolt is an externally threaded fastener that mates with nuts to clamp materials together. Bolts have male (external) threads on the outside that run along a portion of the shaft. One end of the bolt has a head that allows tightening and loosening using tools.

Some key attributes of bolts:

- Externally threaded shank

- Cylindrical shaft with head on one end

- Partial threads run along portion of shaft

- Made of steel alloys but also stainless steel, brass, etc.

- Tightened by applying torque to the head

- Rotates when tightened into nut

- Comes in different grades, diameters, and lengths

- Used with matching nuts to fasten parts together

- Provides clamping force when tightened

Common types of bolts include hex head, socket head, carriage, lag, and U-bolts. You might have seen U-bolts being used in leaf springs as clamps to keep the leaves together. Bolts form the necessary counterpart to nuts in the bolted joint assembly process. They provide adaptable fastening solutions across countless industrial and construction applications.

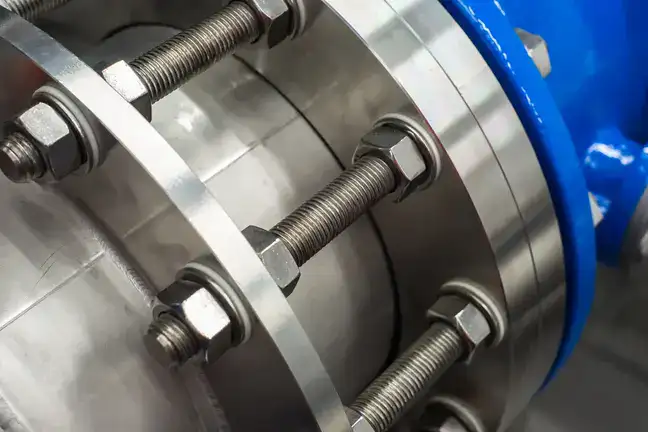

The above image shows nuts and bolts being used as fasteners to hold a coupling mounted on a pipe together.

There’s no doubt that nuts and bolts are an essential tool for mechanical engineers and almost every machine design consist of them .

Difference between Nuts and Bolts

While nuts and bolts work in conjunction to fasten materials together, they have notable differences:

| Nut | Bolt |

|---|---|

| Nut is an internally threaded hole | Bolt is an externally threaded shaft |

| Typically flat with hexagonal or square shape | Cylindrical shape with head on one end |

| Nuts are made of metal alloys including brass, nylon, etc. | Bolt are typically made of steel alloys |

| Stationary when tightened – bolt turns | Rotates when tightened into nut |

| Provides holding force from compressive stress | Provides clamping force from tensile stress |

| Reusable unless damaged | Can deform or fatigue over time |

| Smaller in size than matching bolt | Larger in size than matching nut |

| Has locking mechanisms like nylon inserts | No locking mechanism |

| Comes in standard sizes like M5, M12, 1/4″-20, etc. | Many lengths, diameters, grades available |

| Fully threaded interior hole | Partial external threads on shaft |

| Grips bolt threads when tightened | Grips nut threads when tightened |

| Evenly distributed tightening stress | Stress concentrates under bolt head |

| Allows bolted joint movement if not excessively tightened | Can stretch or elongate joint materials if over-torqued |

| Various types like hex nuts, locknuts, etc. | Types include hex bolts, carriage bolts, etc. |

There are many additional difference between nuts and bolts, but this comparison covers some of the fundamental contrasts between the design and function of nuts versus bolts.

Recommended for you: 37 tools that are a Must-have for every Workshop

Some common questions on Nuts and Bolts

What materials are nuts and bolts made from?

Nuts and bolts can be fabricated from steel alloys, stainless steel, brass, aluminum, nylon, titanium, and other metals or composites. Steel grades like Grade 5, 8, and 12.9 are common. Choice of material depends on factors like strength, corrosion resistance, temperature, weight, cost, etc.

.

What is the difference between a bolt and a rivet?

Bolts use removable threaded fasteners, while rivets use permanent deformed shafts to join materials together.

.

Which is stronger – a bolt or a nut?

For the same size and grade, bolts and nuts have similar strength, but bolts are made of higher strength materials to prevent deformation when tightened.

.

What is the difference between nuts/bolts and washers?

Nuts and bolts fasten components together, while washers distribute stresses and prevent loosening under nut and bolt heads.

.

What are some different types and styles of nuts?

Some nut varieties include hex nuts, wing nuts, lock nuts, flange nuts, square nuts, T-nuts, cap nuts, prevailing torque nuts, castle nuts, and acorn nuts. Each has unique shapes and functional properties.

.

How are bolts classified and what do the classifications mean?

Bolts are classified by properties like material, strength, manufacturing standard, etc. Grade identification like Grade 2, 5, 8, or 12.9 indicates the bolt’s tensile strength. Material grades like 18-8 designate the alloy. Standards like SAE J429 cover mechanical properties.

.

How do you properly size and select nuts and bolts?

Proper nut and bolt sizing requires matching the thread diameter, pitch, and length. Consider factors like load, torque, materials joined, vibrations, etc. Standards provide specifications and tables for selecting the optimal size and grade of nut and bolt for an application.

Here’s a nut and bolt size guide to help you out.

.

What is the difference between a hex bolt and a socket head cap screw?

Hex bolts have a hexagonal head tightened with tools like wrenches, while socket head cap screws have a domed head with an internal socket for Allen wrenches or hex driver bits. Cap screws also meet more stringent property class standards.

.

What causes bolts to loosen over time?

Bolts can loosen due to insufficient initial torque, vibration, improper locking devices, thermal cycling loosening the joint, material creep, overload conditions, and thread wear or deformation, among other factors. Proper design, preparation, and installation methods are key to preventing loosening.

.

How are nuts and bolts installed and removed?

Nuts and bolts must be carefully aligned and tightened to the proper torque spec during installation. Anti-seize, thread lockers, or gasket sealers are often used. Removal methods include wrenches, impact drivers, penetrants, induction heating, and drilling/cutting if seized.

.

How much torque should be applied to tighten nuts and bolts?

Recommended tightening torque varies based on the bolt grade, diameter, lubrication, clamping material, design loading, and other factors. Torque charts, calculators, and product specifications should be consulted to determine appropriate tightening torque values. Proper torque ensures a secure joint without overstressing threads.

.

Conclusion

Nuts and bolts, though they work in tandem, have distinct differences in their design and function as fastening components. This exhaustive guide covers the full spectrum of differences between the design, properties, behavior, selection, and use of nuts as compared to bolts.

Let me know if you have any other nut and bolt questions!